Company History

Water-filled structures were first used in the early 1980’s and were invented by David Doolaege. At that time, concern over environmental damage was in the public spotlight. Sandbagging was the way of choice to control floodwater, but sandbags also presented many problems to anyone trying to implement them. Sandbagging was slow, costly, and labor intensive. There had to be a modern solution to flooding, one of mankind’s’ oldest dilemmas.

Water-filled structures were first used in the early 1980’s and were invented by David Doolaege. At that time, concern over environmental damage was in the public spotlight. Sandbagging was the way of choice to control floodwater, but sandbags also presented many problems to anyone trying to implement them. Sandbagging was slow, costly, and labor intensive. There had to be a modern solution to flooding, one of mankind’s’ oldest dilemmas.

Doolaege realized that all sandbags represent is weight and mass. So why not fill a bag with water? It weighs a lot too, and there is plenty of it in any flood situation. Why not use the onsite water that is causing the problem and make it part of the solution?

He created the first water structure out of three long party balloons in his bathtub. Two balloons were placed inside a third balloon. The two inner balloons were then filled with water. They stretched from one side of the tub to the other, and effectively blocked one side off until the water level rose above it’s height (4 in) and spilled over the top to the other side. This was the first structure ever to use water to control water.

Doolaege then moved his scientific test lab from the bathtub to a plywood test in his front yard. He placed a single water-filled balloon on the plywood and raised one side. It rolled off immediately. He next placed seven single tubes of water behind a structure of the same design used in the bathtub. Then one end of the plywood was picked up to waist height, creating a severe incline. The seven individual tubes all rolled down the plywood until they came in contact with the water structure. Not only did the structure not roll down the incline, it stopped the other seven tubes from rolling down the plywood as well. The tube of water next to the water structure was popped using a pin, and immediately the other six tubes rolled down until they were again stopped by the water structure. This process was repeated until all seven tubes were popped, leaving only the water structure on the inclined plywood board. The plywood was raised all the way to chest height before the structure slid down the face of the board. The gravity of the incline became too great for the weight and mass of the water-filled structure to cause enough friction to hold onto the face of the plywood.

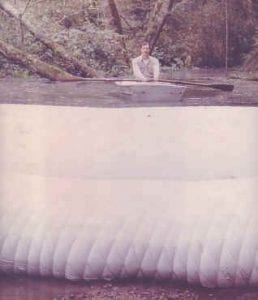

Doolaege then moved his scientific lab to a creek behind the house. After conquering that, he moved his research to the local Van Duzen river. During the acquisition of permits to conduct his in-stream experiments, Doolaege gained the support of several local officials who dealt with water quality issues. They were the ones who originally suggested that Doolaege use his product for construction applications.

The old methods of earthen fill discharge did not comply with the new Clean Water Act guidelines. Earthen fill-material discharges associated with cofferdams caused severe environmental damage, according to the EPA. They were happy to see other alternatives being explored. CalTrans remembered him when they had to deal with a large landslide that had fallen into the Eel River. They decided to use water-filled cofferdams because a female Bald Eagle and her chicks were roosting almost directly across the river. Water turbidity from the job site, using conventional methods of earthen fill discharges to create the needed cofferdam, would cloud the river substantially. This would impair the eagle’s ability to fish that portion of the river.

The old methods of earthen fill discharge did not comply with the new Clean Water Act guidelines. Earthen fill-material discharges associated with cofferdams caused severe environmental damage, according to the EPA. They were happy to see other alternatives being explored. CalTrans remembered him when they had to deal with a large landslide that had fallen into the Eel River. They decided to use water-filled cofferdams because a female Bald Eagle and her chicks were roosting almost directly across the river. Water turbidity from the job site, using conventional methods of earthen fill discharges to create the needed cofferdam, would cloud the river substantially. This would impair the eagle’s ability to fish that portion of the river.

This was the first chance to use water in a real-life construction application, and the technology of in-stream water control has progressed from there to what you see on this web site today.

Contact us today to find out more information or for a free quote on AquaDams for your flood control projects, please contact us online or call us now at 1-800-682-9283.